Raziskovanje vsestranskih lastnosti PP folij v termoformirani embalaži za hrano

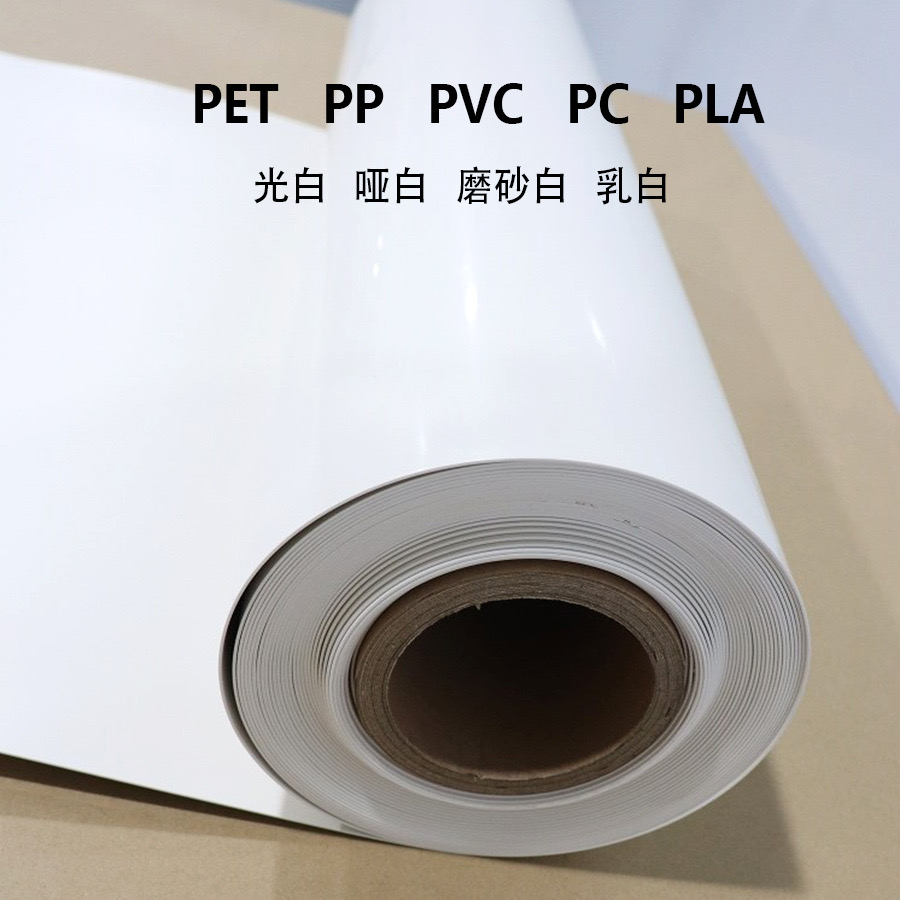

Material: PP toplotno oblikovana plošča

Debelina 0,25-0,9 mm/prilagajanje

Velikost: 300 mm/prilagajanje

GRADE: Film za živila

barva: črna/bela/prilagajanje

lokacija: Kitajska

uporaba: za pladenj za hrano, mikrovalovno posodo za hrano

- TOPLEADER

- Kitajska

- 15 DELOVNIH DNI

- 5000T/M

- informacije

- video

- prenos

Introduction

Polypropylene (PP) films have become a cornerstone in the packaging industry, particularly in the realm of food service due to their exceptional properties. This article delves into the characteristics of PP films that make them ideal for thermoformed food packaging, exploring their advantages, applications, and future prospects.

Properties of PP Film

Mechanical Strength and Flexibility: PP films are renowned for their balance between rigidity and flexibility, which is crucial for thermoforming processes. The mechanical strength of PP allows it to withstand the rigors of manufacturing and handling without compromising the integrity of the package. This strength is especially evident in films that are biaxially oriented (BOPP), where the molecular chains are aligned in two directions, enhancing tensile strength and stiffness.

Thermal Resistance: One of the defining features of PP films is their high thermal resistance. With a melting point around 160°C to 170°C, PP films can endure pasteurization, sterilization, and even microwave cooking without deforming or releasing harmful chemicals into food. This makes PP an excellent choice for packaging items that require heating, such as ready meals or snacks.

Barrier Properties: PP films offer good barrier properties against moisture and oxygen, although not as high as some other materials like PET. However, when used in combination with other materials like EVOH or metallized layers, PP can achieve enhanced barrier characteristics, significantly extending the shelf life of perishable foods by preventing spoilage.

Optical Clarity: Cast PP films are known for their clarity and gloss, providing an aesthetically pleasing packaging solution that can showcase food products effectively. This clarity is particularly important in food packaging where visual appeal can drive consumer purchase decisions.

Chemical Resistance: PP is resistant to many chemicals, including acids, bases, and solvents, which is vital for packaging foods with high moisture content or those that might interact with less inert materials. This resistance ensures that the packaging does not alter the taste or safety of the food product over time.

Recyclability: PP films are 100% recyclable, aligning with the growing environmental consciousness among consumers and regulatory bodies. This recyclability reduces the environmental footprint of packaging waste and supports sustainability initiatives in the food industry.

Applications in Food Packaging

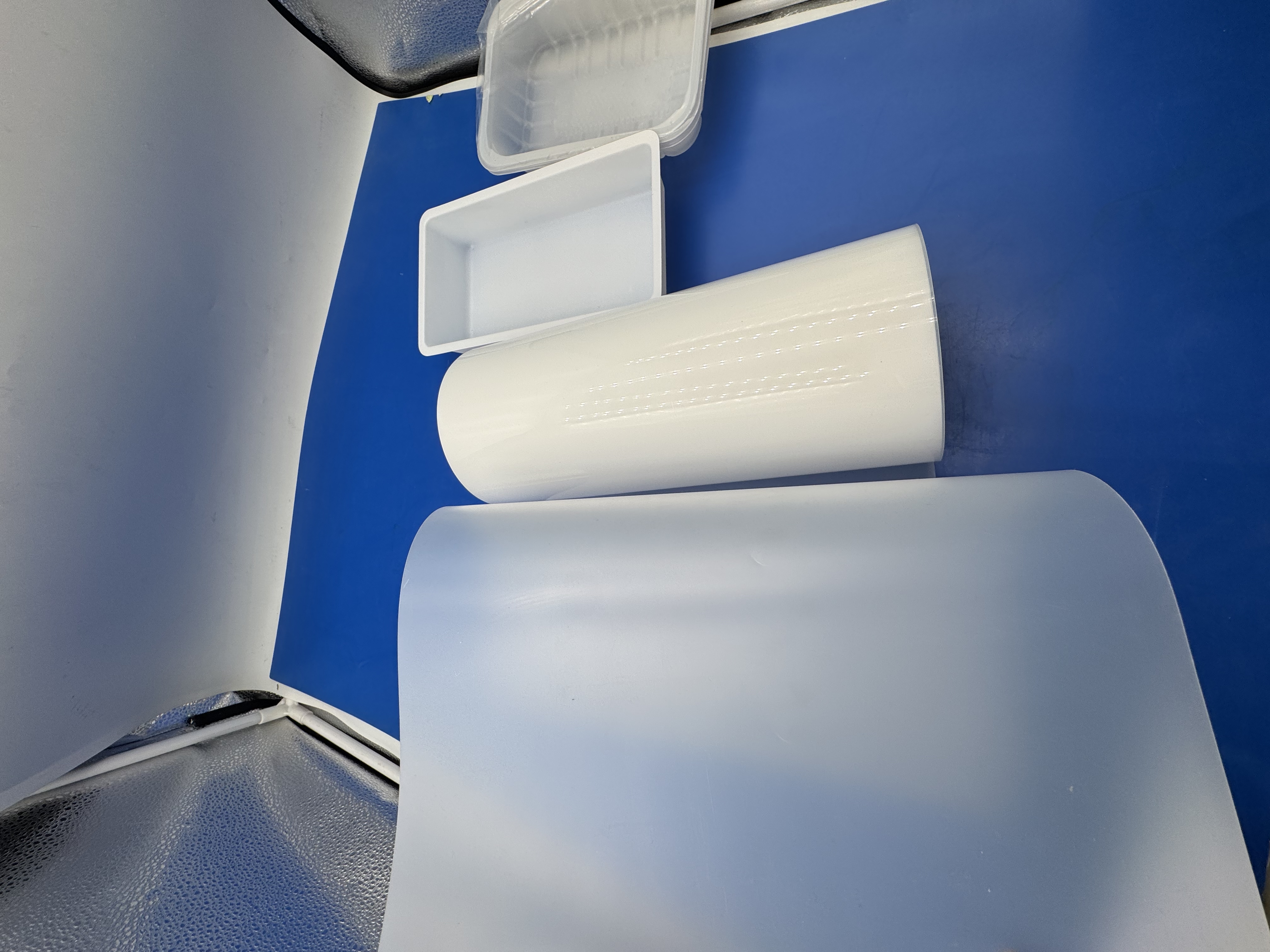

Thermoformed Containers: PP's suitability for thermoforming makes it ideal for creating rigid containers for a variety of food products. From deli containers for salads to trays for meat and cheese, PP's high heat resistance and good formability allow for complex shapes that cater to the specific needs of food packaging. These containers are often used in supermarkets where they must maintain their shape and protect food integrity from shelf to home.

Microwaveable Packaging: The thermal stability of PP enables the production of packaging that can go directly from freezer to microwave, offering convenience to consumers. This is particularly useful for ready meals, where the packaging must withstand heating without compromising safety or quality.

Freshness Preservation: For products like fresh pasta, snacks, or pet food, PP films can be tailored to provide the necessary barrier against oxygen and moisture. This preservation of freshness is crucial in extending shelf life, reducing food waste, and ensuring that products reach consumers in optimal condition.

Peelable Lidding Films: PP films can be engineered to be peelable, providing ease of access to food products while maintaining a tight seal during transport. This is particularly useful for packaging that needs to be opened and resealed, like individual servings of cheese or yogurt.

Customizable for Branding: The clarity and printability of PP films allow for vibrant branding and product information directly on the packaging. This aspect is critical in food marketing, where packaging often plays a significant role in brand recognition and consumer choice.

Challenges and Innovations

Despite its advantages, PP has some limitations, such as not being inherently an excellent oxygen barrier, which can be mitigated through co-extrusion with barrier materials. Innovations in PP film technology include:

Multi-layer Films: Combining PP with other polymers like PA, EVOH, or PE to enhance barrier properties without losing the mechanical benefits of PP.

Active Packaging: Incorporating features like antimicrobial agents or oxygen scavengers directly into the film to actively maintain food freshness.

Sustainable Practices: Developing more sustainable versions of PP, like bio-based PP or improving recycling processes to ensure closed-loop systems.

Conclusion

PP films stand out in the packaging industry for their versatility, particularly in food service packaging. Their mechanical, thermal, and barrier properties, combined with the ability to be recycled, make them indispensable for modern food packaging solutions. As consumer demands evolve towards sustainability and convenience, PP films continue to adapt, offering innovative solutions that meet these changing needs.

V 15-20 dneh po prejetem plačilu...more