PP/EVOH/PP embalažni list

2025-03-27 15:55Introducing our premium line of Thermoforming PP sheets, designed to meet the highest standards in food-grade packaging and product protection. These sheets, crafted from a blend of PP (polypropylene) and EVOH (ethylene vinyl alcohol), deliver exceptional barrier properties that are ideal for a variety of packaging applications. Whether you're looking for PP EVOH high barrier sheet for packing or Food grade PP EVOH packaging sheet solutions, our products offer unmatched performance and reliability.

Our high barrier PP EVOH sheets are engineered to preserve the freshness and quality of packaged goods by effectively blocking moisture, oxygen, and other environmental contaminants. These sheets are perfect for industries requiring superior packaging integrity, such as food processing, pharmaceuticals, and consumer goods. Key attributes include enhanced durability, thermal stability, and ease of thermoforming into various shapes and sizes.

The critical features of our Thermoforming PP EVOH sheets include their ability to provide superior barrier protection against gases, odors, and UV rays. With excellent formability, these sheets can be shaped into trays, blisters, and clamshells, ensuring optimal fit and functionality. The combination of PP and EVOH creates a material that is not only environmentally friendly but also cost-effective in large-scale production environments. Additionally, our sheets are compliant with global food safety regulations, making them an ideal choice for businesses seeking to enhance their packaging solutions.

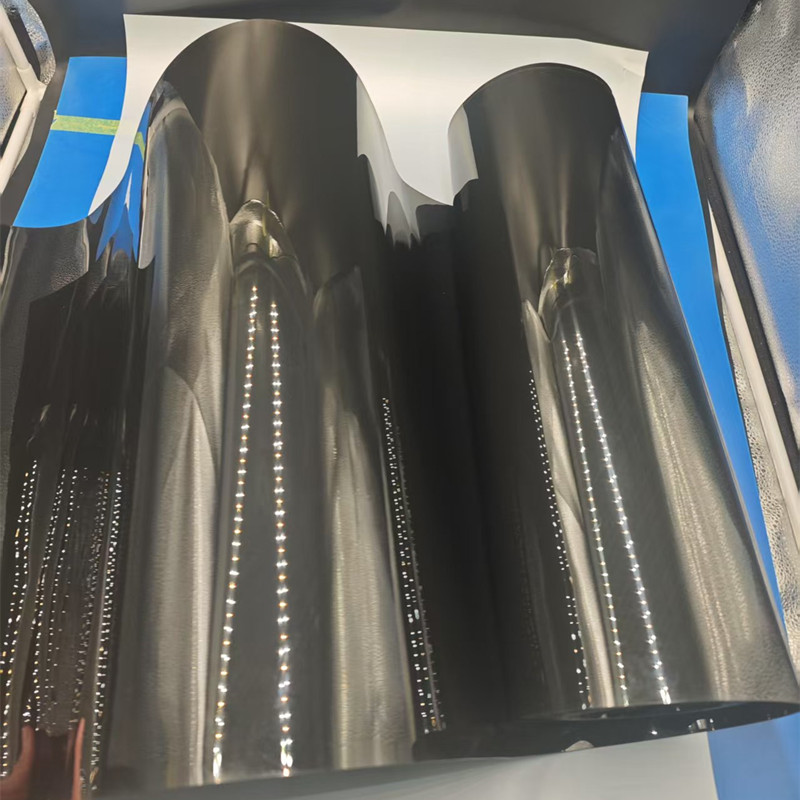

These high barrier PP EVOH sheets are manufactured using advanced extrusion technology, ensuring consistent thickness and surface quality across each roll. The PP EVOH composite provides an optimal balance between mechanical strength and flexibility, allowing for seamless integration into existing packaging lines. Whether you need sheets for vacuum-forming or pressure-forming applications, our products ensure precision and efficiency at every step of the process. The sheets are available in various thicknesses and widths, catering to diverse packaging needs while maintaining their core properties of high barrier performance and food-grade compliance.

Our Thermoforming PP EVOH sheets find application in numerous scenarios, including ready-to-eat meal packaging, fresh produce preservation, and medical device containment. They are particularly suited for industries where shelf-life extension is crucial, such as the dairy, meat, and seafood sectors. By utilizing these sheets, businesses can significantly reduce product spoilage, minimize waste, and improve overall supply chain efficiency. The versatility of our sheets ensures they can adapt to both small-batch and large-scale production demands, providing a scalable solution for growing enterprises.

User reviews highlight the superior quality and performance of our high barrier PP EVOH sheets. Many customers praise the sheets' ability to maintain product freshness over extended periods, reducing the need for additional preservatives. The ease of thermoforming and compatibility with standard machinery has been noted as a key advantage, streamlining production processes and minimizing downtime. Testimonials also emphasize the material's eco-friendly nature and its contribution to sustainable packaging practices, aligning with modern business goals.

Frequently asked questions about our Thermoforming PP EVOH sheets often revolve around their suitability for specific packaging types and their resistance to extreme conditions. Users inquire about the sheets' performance under high humidity environments and their compatibility with automated packaging systems. Others seek clarification on the availability of custom sizes and the potential for incorporating additional functional layers. Rest assured, our team is committed to addressing all queries and ensuring that our products meet the unique requirements of each client.