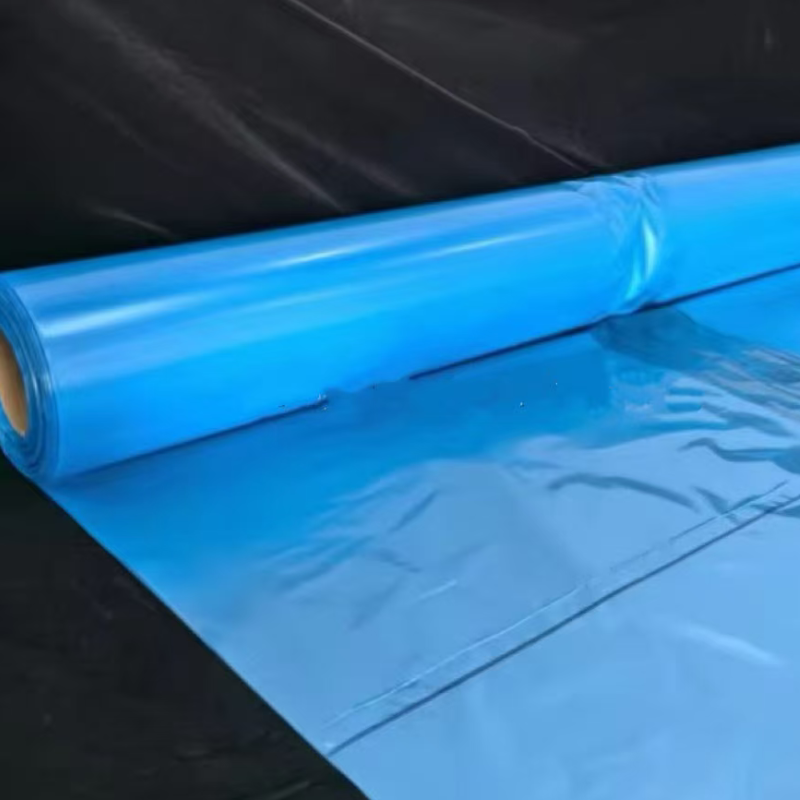

Večplastna koekstrudirana folija, PA/PE FOLIJA

Večplastna koekstrudirana folija, PA/PE srednje pregradna folija, ki se uporablja za pakiranje živil.

"Orožje za ohranjanje svežine" v embalaži za živila: večplastna koekstrudirana srednje velika zaščitna folija PA/PE – zaščita svežine živil s prednostmi kompozita

- top leader plastic

- Kitajska

- 16 delovnih dni

- 200 ton/mesec

- informacije

Multilayer co-extruded

The "Freshness-Locking Weapon" in Food Packaging: PA/PE Multilayer Co-extruded Medium Barrier Film – Protecting Food Freshness Through Composite Advantages

In the food packaging industry, "barrier properties" are a core requirement for extending shelf life. PA/PE multilayer co-extruded medium barrier film (including PA/PE base film and stretch film) achieves multiple layers of protection—oxygen barrier, moisture barrier, and leak-proof—through a layered composite of nylon (PA) and polyethylene (PE). It also possesses tensile strength and ease of heat sealing, making it the mainstream packaging choice for meat, cooked food, and snacks, perfectly balancing "freshness-locking function" and "usability compatibility."

PA/PE multilayer co-extruded film is not a single material; rather, it combines PA layers, PE layers, and optional adhesive layers (such as EMA) into a single unit through a co-extrusion process. A typical structure is "PA (outer layer) + adhesive layer + PE (inner layer)," with a thickness typically between 0.08-0.2mm. Each layer complements the other's function, forming a medium barrier capability.

Outer Layer: PA (Nylon) 20%-30% provides core barrier properties – its oxygen barrier rate is 10-15 times that of pure PE film, slowing down food oxidation (such as meat spoilage and snack rancidity); it also improves the film's tensile strength and puncture resistance, preventing punctures by sharp objects during transportation.

Inner Layer: PE (Polyethylene) 60%-75% handles heat sealing and contact functions – PE has a low heat sealing temperature (120-150℃) and a heat sealing strength ≥3.0N/15mm, ensuring a leak-proof seal; food-grade PE material is non-toxic and odorless, conforming to GB 4806.7 standards, and can directly contact food.

In short, this film's logic is "PA layer for oxygen barrier and puncture prevention + PE layer for sealing and safety." The multi-layer co-extrusion process ensures a tight bond between the layers, avoiding the glue residue problems of traditional composite films (such as dry lamination), making it more suitable for the safety requirements of food packaging.

II. Core Advantages: Medium Barrier Strength + Practical Performance, Meeting Essential Food Packaging Needs

The advantages of PA/PE multilayer co-extruded film are concentrated in three dimensions: "barrier properties, processability, and safety." It addresses the pain points of food preservation while adapting to industrial packaging processes.

1. Medium Barrier Strength, Precise Freshness Locking

Dvojna prednost pri zaščiti pred kisikom in vlago – zadovoljevanje potreb mesa, kuhane hrane in pekovskih izdelkov po zaščiti pred kisikovo pregrado in preprečevanju kvarjenja (npr. podaljšanje roka uporabnosti ohlajenega mesa za 3–5 dni in piškotov za 1–3 mesece), hkrati pa je stroškovno učinkovitejša od visoko pregradnih folij (kot so PA/EVOH/PE), zaradi česar je primerna za embalažne proračune živil za množični trg;

Stabilna in nezmanjšana trdnost pregrade: Postopek koekstruzije odpravlja lepilo med plastmi, kar zagotavlja, da temperatura in vlažnost ne vplivata na delovanje pregrade (stabilno delovanje v območju od -20 ℃ do 60 ℃). Tudi pri uporabi za ohlajena živila (kot so jogurt in mesni izdelki pri nizki temperaturi) ali shranjevanje pri sobni temperaturi (kot so oreščki in čips) še naprej zagotavlja zaščito pregrade in preprečuje prezgodnje kvarjenje.

2. Visoka natezna trdnost in žilavost, primerna za distribucijo

Odpornost proti nategu + odpornost proti prebadanju: Natezna trdnost plasti PA je ≥50 MPa, raztezek pri pretrgu plasti PE pa ≥300 %. Trdota kompozitne folije daleč presega trdnost čiste PE folije. Raztegljivo folijo je mogoče ročno ali mehansko raztegniti za zavijanje hrane (na primer pladnjev za cele škatle sadja ali mesa), s stopnjo raztezanja 200 %–300 %. Po ovijanju se tesno prilega, da se med transportom ne zrahlja. Spodnja folija, ki se uporablja pri izdelavi vrečk, lahko prenese vlečenje pakirnih strojev in stiskanje hrane ter se ne strga ali poškoduje zlahka.

folija, PA/PE srednje pregradna folija, ki se uporablja za pakiranje živil.

V 15-20 dneh po prejetem plačilu...more